Synopsis

- Governments, industries, and consumers demand increased plastic recycling rates and increased recycled content, particularly in the world of plastics.

- There is public and regulatory demand for recycled/virgin ratios to be tracked, documented and communicated.

- The primary chain-of-custody approach proposed for plastic waste recycling is mass balance. There are several mass balance approaches, which differ in their attribution and reattribution (credit) rules.

- The main proposed mass balance approaches are Proportional (or rolling average), Fuel-excluded (or fuel exempt), and Polymers-only – the latter two allowing reattribution.

- Reattribution methods will be criticized as greenwashing and destroy consumer trust in the recycling and manufacturing industries.

- Reattribution methods will decrease investments in more efficient technologies with better positive environmental impact.

- Reattribution methods will create an unfair playing field and disadvantage technologies with better efficiency, higher yield, and higher positive impact.

- Reattribution methods will lock in suboptimal technologies and discourage innovation.

- Reattribution methods will roll back positive developments in the policy conversation on the chemical industry.

- Reattribution methods undermine the fundamental purpose of mass balance and recycled content and will have negative environmental consequences – decreased recycling rates, increased carbon emissions, and slower defossilization of industry.

- Proportional mass balance attributes to all outputs of the recycling process the same recycled/virgin ratio as the feedstock mixture, with no reattribution or credit transfer allowed among outputs or production locations.

- Proportional mass balance is simple, clear, and intuitive. It is transparent and easily communicated to the public, policymakers, and regulators. Most importantly, it serves the goals that are the basis of the entire recycling/recycled content endeavor.

- Therefore, the only acceptable mass balance approach is “proportional with no reattribution or credit transfer”.

Environmental goals drive the demand for recycled content

In an era marked by intensifying environmental concerns, the quest for sustainable solutions has risen to the forefront of global priorities. One of the prominent tools, conceptually and practically, that emerged in the field of environmental policy is circularity, or “the circular economy”. Two pivotal challenges related to circularity are increasing plastic recycling rates and integrating recycled materials into products and packaging.

Circularity is not restricted to the narrow scope of plastic-to-plastic but also applies to plastic-to-petrochemicals. This more comprehensive approach not only augments recycling rates but also helps industries free themselves from dependency on fossil fuels, thus reducing carbon emissions.

This circularity is particularly relevant to the chemical industry – Europe’s third-largest emitter of carbon dioxide, mainly as a result of its massive reliance on fossil fuels as feedstock. For this reason, this industry has become one of the key pillars of the European Commission’s carbon emissions reduction and defossilization strategy.

Simultaneously, consumer demand for products and packaging containing recycled content, particularly recycled plastic, has surged. Against this backdrop, national governments, supranational organizations, and industries are committed to increasing plastic recycling rates and the percentage of recycled content in products and packaging. But while it is desirable to make products with 100% recycled material, this presents enormous challenges in today’s petrochemical complex.

Implementing recycled content requires chain-of-custody accounting

Mixing virgin and recycled plastic creates a new challenge: tracking, documenting, verifying, and communicating recycled content clearly and consistently.

Tracing the flow of materials through a complex value chain is called “chain-of-custody”, with various approaches seeking to achieve this goal. Navigating the intricate terrain of chain-of-custody methods in plastic recycling reveals a spectrum of approaches, each bearing distinctive characteristics that influence the attribution of recycled content. Among these methods, the mass balance framework emerges as a central paradigm, encompassing several models that differ in (1) their attribution rules – what outputs they can/must include/exclude in the calculation, and (2) their credit transfer (reattribution) rules – whether they allow attributed recycled content to be reallocated.

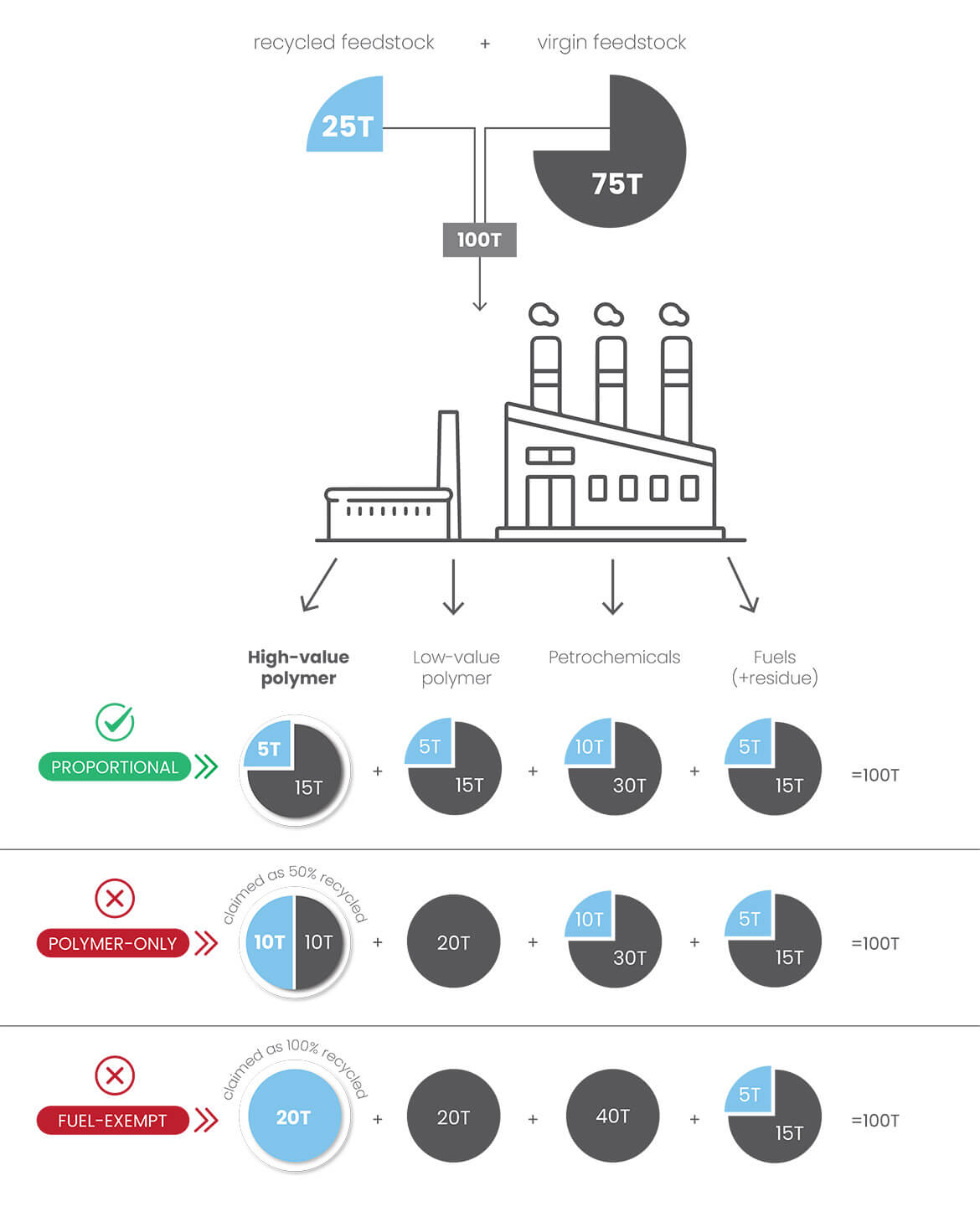

The main mass balance methods currently proposed for plastic recycling are:

- Proportional (rolling average) mass balance – attributes to all outputs of the recycling process – energy, fuel, polymers, petrochemicals, and residues –the same recycled content ratio as the feedstock mixture. No reattribution or credit transfer is allowed between outputs or production locations. A variant of the proportional approach, called “rolling average”, accounts for across-batch variations by averaging.

- Fuel-excluded (fuel-exempt) mass balance – allows the reattribution of the recycled proportion from products and outputs other than fuel and energy to the polymer outputs, which increases their declared recycled content ratio.

- Polymers-only mass balance – only allows the reattribution of the recycled proportion between polymer outputs.

In the figure shown here, these three methods are outlined as they apply to a hypothetical scenario. For the sake of simplicity, we assume there’s no mass loss, and consider all materials to have identical mass, resulting in a straightforward conversion where 100 tons of inputs yield 100 tons of combined outputs of various types. In this scenario, 25 tons of recycled feedstock (pyrolysis oil, plastic waste, etc.) are blended with 75 tons of virgin feedstock (naphtha, virgin plastic, etc.), resulting in a feedstock mixture containing 25% recycled input. This mixture is used to create 20 tons of a high market-value polymer, 20 tons of a lower-value polymer, 40 tons of petrochemicals, and 20 tons of fuels.

- Under proportional attribution, all outputs have 25% recycled content, reflecting reality.

- Under polymers-only reattribution, the manufacturers are allowed to “transfer” recycled content between the polymers. Therefore, they reallocate 5T of recycled content from the low-value polymer to the high-value polymer, claiming 50% recycled content.

- Under fuel-exempt reattribution, the manufacturers are allowed to transfer from all outputs, excluding fuel and residue. They, therefore, reallocate 15T of recycled content to the high-value polymer, claiming for it 100% recycled content, where in reality it is only 25%.

Choosing the right mass balance approach is crucial

Governments and other organizations will soon be implementing policies – regulations, penalties, tax breaks, subsidies, and others – meant to incentivize recycling, circularity, and defossilization, and to disincentivize practices and technologies that are less sustainable and environmentally friendly. These policies will play a significant role in shaping market conditions and determining the direction the market takes for decades to come. They will play a crucial factor in determining which technologies and solutions become prominent and which die, either of old age – obsolescence, or at birth – before they go to market.

Such governments and organizations would have to implement various methodologies to determine what practices and technologies are more sustainable and environmentally friendly, or less, and would implement policies to incentivize/disincentivize these practices accordingly. Therefore, the choice of a mass balance approach carries immense consequences.

The current debates around mass balance allocation methods have legal implications at the level of the European Union. In the context of the Single Use Plastic Directive (SUPD), the European Commission needs to develop harmonized methodologies to assess the achievement of the recycled content targets for SUP bottles, and the specific targets for PET bottles. The institution already issued a first implementing act containing the methodology for mechanical recycling, and committed to adopt a second one on chemical recycling before the end of the current political mandate.

Considering this implementing act will be the first regulation on calculating recycled content for products and intermediates from chemical recycling at the European level, this implementing act will likely be a blueprint for future regulation in Europe. The methodology detailed in it might be later reused in future secondary legislation concerning, for example, packaging (with the Packaging and Packaging Waste Regulation) or products (in the context of the Ecodesign Regulation for Sustainable Product Regulation).

Therefore, the choice of approach will act as a critical inflection point, with ramifications that will profoundly shape market perceptions, consumer trust, technological trajectories, and the broader transition toward a circular economy. Mass balance will affect public opinion and the reputation of the plastic, oil, petrochemical, manufacturing, and recycling sectors, which will be perceived as either environmentally-conscious innovators or greenwashing dinosaurs. Therefore, the industry must engage in an honest and transparent discussion and keep in mind the fundamental goals of the entire recycling/recycled content endeavor. This discussion should not ignore the long-term implications because correcting the technological, regulatory, and market courses of whole industries is very difficult once they are set and gain momentum.

This article argues that reattribution methods will harm the long-term goals of all stakeholders and that the only legitimate and constructive approach is strict proportional mass balance.

Reattribution will undermine transparency and consumer trust

The trend in public demand and government policy is toward more transparency in every part of the consumer market. Reattributing recycled content to certain materials and products will make their recycled ratios appear higher than they actually are – going against this trend.

“Creative” accounting practices are already criticized as greenwashing by various stakeholders, such as activists, NGOs, and policymakers. This criticism will inevitably reach wider audiences and news media. It will create public backlash that will likely be directed against the entire recycling sector, as well as petrochemical and plastic manufacturers, who are already perceived as “bad actors”.

Basing recycled content on an opaque accounting system does not help create trust and transparency. At best, consumers will stop paying attention to declared recycled content. At worst, they will be perceived as greenwashing, and companies will face painful backlash, affecting their image and profits.

Consider a hypothetical scenario involving a company that produces plastic packages touting a commitment to sustainability and prominently advertising a high recycled content ratio of 100% based on mass balance. If the scenario involves reattribution, the company exploits the flexibility offered by these methods and incorporates only a small percentage of chemically recycled material into the production process.

- Using reattribution, the company claims the entire 100% recycled content ratio for its plastic packages, bolstering its image as an environmentally conscious entity.

- Upon closer scrutiny, it becomes apparent that most of the packages’ composition, around 90%, originates from fossil feedstocks.

- The disparity between the advertised and perceived 100% and the actual 10% recycled content creates a palpable dissonance for consumers who believed they were supporting a genuinely sustainable product, leading to disillusionment and distrust.

Reattribution will discourage investments and harm innovation

One of the main justifications for loose mass balance methods is that they will help drive investments in fledgling technologies, especially in the chemical recycling sector. While the short-term allure of compliance and financial benefits is appealing, the long-term impact on innovation and technological advancement can be detrimental. Implementing reattribution methods will likely hinder innovation and stifle investment in several ways:

- Short-term gains, long-term complacency: Reattribution methods provide a too-easy path to achieving impressive but untrue recycled content ratios without requiring substantive changes in production processes. This ease could create a false sense of accomplishment, leading manufacturers to become complacent and forgo more meaningful investments in truly innovative recycling technologies.

- Inhibition of breakthrough technologies: True innovation often requires substantial research, development, and risk-taking. Reattribution methods offer a convenient way to meet environmental, sustainability, and climate goals and could divert attention and resources away from the pursuit of breakthrough recycling technologies. Manufacturers might opt for suboptimal solutions that rely on reattribution rather than exploring novel approaches that could have a higher environmental impact and offer genuine advancements in recycling. In other words, if the label of “100% recycled content” can be achieved through technological development or through creative accounting, there will be less incentive to invest in technology.

- Market inertia and technological lock-in: Reattribution methods could result in the perpetuation and dominance of existing technologies, particularly those designed for fossil feedstocks. This market inertia, fueled by reattribution’s ease, might result in the “lock-in” of technologies that were chosen for short-term compliance rather than long-term environmental effectiveness.

- Missed opportunities for holistic innovation: The plastic recycling landscape is multidimensional, involving chemical, mechanical, and hybrid approaches. By focusing on numerical compliance, reattribution methods might overshadow the potential for holistic innovations that combine various methods for maximum efficiency and sustainability.

Innovation and investment are crucial for progress. Reattribution methods, while offering initial attractions, can inadvertently undermine the foundations that drive the development of advanced recycling technologies. A shift toward embracing transparent, forward-looking, and innovation-centric practices is crucial to fostering a landscape characterized by continuous improvement, real environmental impact, and transformative solutions.

Reattribution will result in unfair market conditions with significant advantages to less environmentally friendly technologies

Reattribution of calculated recycled content will enable manufacturers to maximize profits on existing legacy operations that were designed for processing fossil fuels and thus can only accept limited amounts of recycled feedstock (non-hydrotreated pyrolysis oil). As a result, the recycled/virgin ratios they can handle are low. This limiting factor makes it highly likely that legacy systems will never become significant contributors to plastic recycling and circularity. Fuel-exempt mass balance will disproportionally help legacy fossil processing facilities “achieve” recycled content with minimal amounts of plastic waste-derived pyrolysis oil. This will likely harm the incentive of the petrochemical industry to defossilize and allow it to continue doing business as usual.

Moreover, reattribution mass balance methods will create an unfair playing field for those manufacturers and recyclers who already use 100% plastic waste as feedstock. Manufacturers could claim a green premium on products containing little or no sustainable feedstock and will have a cost advantage over products consisting of sustainable feedstock.

Reattribution will slow defossilization, decrease recycling rates, and increase carbon emissions

As mentioned, implementing reattribution will likely disincentivize manufacturers from replacing their fossil feedstocks with sustainable feedstock, impeding efforts to defossilize industry, increase recycling rates, and fight carbon emissions. Moreover, these creative accounting approaches could be used to mask low yields throughout the whole waste-to-final-product value chain and mislead regulators and the public.

Lastly, the focus of the chemical industry policy conversation might shift away from feedstock back to the energy side. The chemical sector is Europe’s largest industrial senergy consumer and the third-largest industry subsector in terms of direct CO2. A significant factor behind this position is that the biggest portion of the chemical subsector’s fuel intake is utilized as feedstock, serving as a raw material input rather than an energy source. Until recently, policy conversation focused on scope 1 and 2 emissions, ignoring scope 3 emissions. However, for many primary petrochemical outputs, the largest portion of their carbon footprint originates from the carbon embedded in their end products and released upon end-of-life (scope 3). This led to a realization that the main effort of defossilization should be dedicated to the feedstock aspect and not just the energy aspect of the industry – shifting it away from its current dependency on fossil fuels and toward a more sustainable carbon source, like plastic waste. If permissive mass balance methods become the norm, the chemical industry’s shift toward sustainability will likely slow down.

All these consequences could prevent governments and industries from fulfilling their environmental and sustainability goals or fulfilling them on paper only.

A strict proportional, no-credit, no-reattribution mass balance is the only approach that will promote sustainability, reduce carbon emissions, and ensure environmental innovation

Mass balance is a set of rules that matches inputs such as plastic waste with outputs from a recycling or production process to determine the recycled content of products and packages and advertise them as more environmentally friendly.

As argued here, mass balance approaches that allow fossil feedstock to be labeled as recycled through reattribution and creative calculations could harm all the positive goals that make the basis of the entire endeavor. Reattribution/credit transfer methods jeopardize the fundamental purpose of recycling – fighting pollution and improving sustainability. They create an unfair and counterproductive playing field by providing an advantage for companies and products with low actual recycled content over those with high recycled content. The lower one’s environmental performance is – the higher it will benefit from a loose mass balance calculation method.

In contrast, the proportional attribution approach assigns outputs with the same recycled content ratio as the ratio of recycled to virgin inputs. It simply and straightforwardly reflects the chemical reality. A kilogram of plastic contains many sextillions (1023) of molecules, depending on the molar mass of the plastic. When pyrolysis oil – oil made from broken-down plastic waste, is mixed with virgin oil and then used to make plastic, fuel, or petrochemicals such as solvents, oils, and waxes – any output will contain the same recycled/virgin ratio of the original mixture.

Proportional mass balance is simple, clear, and intuitive – both as a calculation method and as a chain-of-custody accounting protocol. It is transparent and easily communicated to the public, policymakers, and regulators.

In addition, proportional mass balance is the only approach that does not lead the chemical recycling industry into a blind alley characterized by discredit, disinvestment, and stagnation that, at best, will ensure it will always remain a niche technology.

If the chemical recycling industry wishes to gain market, policy, and public acceptance as a viable solution for plastic waste, it should only use proportional mass balance and promote it as the only acceptable chain-of-custody approach.