Synopsis

- The EC wants significant (1) carbon emission reduction, (2) defossilization (reduced dependency on fossil fuels), and (3) increased resource efficiency.

- Circularity is one of the primary tools the EC advocates to achieve these goals.

- The EC is specifically targeting the chemical industry for emission reduction and defossilization.

- Plastic waste recycling is a path to circularity, reducing fossil use on the feedstock and output sides.

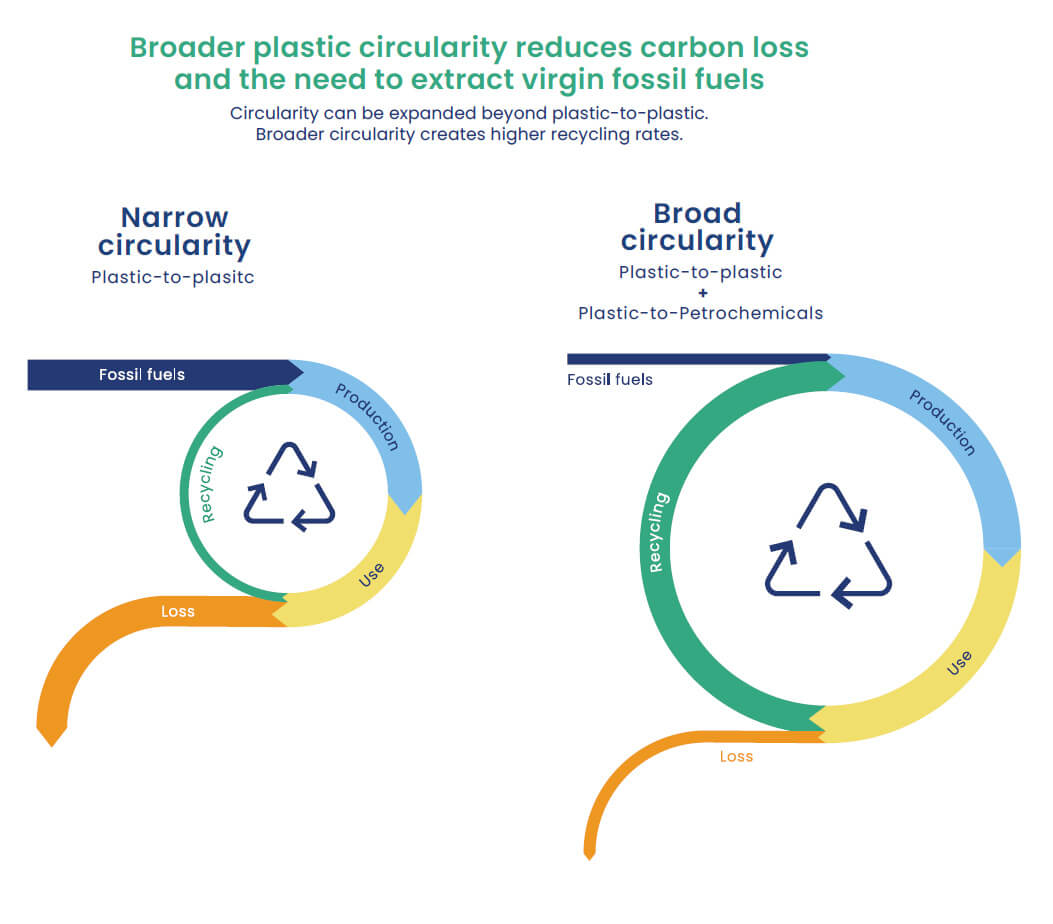

- Unfortunately, the conversation on plastic circularity is unnecessarily restricted and focused on plastic-to-plastic recycling.

- Plastic-to-(petrochemical)-products is a viable additional mode of recycling, with its own unique advantages,opportunities, and value.

- European and American policymakers recognize the numerous benefits of this approach.

- Without this broader concept and implementation of circularity, the EU and the European chemical industry areunlikely to achieve their environmental goals.

Introduction

The European Commission’s Green New Deal contains ambitious carbon emission reduction goals. One goal is to shift at least 20% of the chemical and plastic sector’s carbon use from fossil to sustainable non-fossil sources by 2030.

Since the chemical industry is a major fossil fuel consumer and a major contributor to carbon dioxide emissions, the EC put it at the center of its emission reduction and defossilization plan.

In January 2023, The EC published “Transition Pathway for the Chemical Industry” – a document outlining planned changes to regulatory, financial, infrastructural, and other areas relevant to the chemical industry.

One of the central concepts in this transition plan is “circularity” – “…returning [materials and resources] into the product cycle at the end of their use while minimizing the generation of waste”. The document emphasizes carbon circularity, with plastic waste recycling receiving attention as a more sustainable feedstock and an avenue for increased resource efficiency, increased industrial symbiosis, and more.

In this article, I argue that plastic circularity should include, and indeed was always meant to include, all outputs of plastic recycling – not just new plastic – and that without broadening the current, unnecessarily restricted concept of circularity, the petrochemical industry is unlikely to achieve its “net zero” ambitions.

The EC’s vision for the chemical industry’s transition to sustainability relies on circularity

The EU is the second largest chemicals producer in the world. The chemical industry is the fourth largest industry in the EU. It is the EU’s third largest emitter of carbon dioxide, largely because of its massive reliance on fossil fuels as feedstock – as raw material. For this reason, the chemical industry is at the center of the EC’s carbon emissions reduction and defossilization plan.

One of the EC’s main visions for the chemical industry, stated in the 2020 document “Chemicals Strategy for Sustainability”,1 is that chemicals “are produced and used in a way that maximizes their contribution to society while avoiding harm to the planet”.

The EC proposes several approaches to achieve these goals – carbon emissions reduction, defossilization, and resource efficiency (maximizing societal benefit while reducing environmental harm) – with circularity at their core. Circularity plays an essential part in several topics covered in the “transition pathway” document:

- Preventing losses of materials by increasing circularity.

- Designing industrial processes that include plastic waste as a resource. This also supports waste reduction since it reduces waste generation and increases waste utilization.

- Improving collaboration in value chains (via the Circular Cities and Regions initiative), with local plastic waste replacing imported fossil fuels as raw material for industry (which also reduces international value chain challenges).

- Product design and re-design (the Ecodesign for Sustainable Products Regulation concept) in product categories such as detergents, paints, and lubricants2 that can use intermediate materials such as waxes, oils, and solvents that are ade from plastic waste. This will also increase the recycled content of such industrial and consumer products.

- Using waste as an alternative feedstock, particularly through chemical recycling: “These technologies involve recycling with a high yield a broad range of plastic waste, including hard-to-recycle plastics, into high-purity products (such as waxes, oils, and solvents) that can be used across a variety of different industries… enabling the circular production of fossil-free chemicals.”

In summary, one of the EC’s main strategic pillars is: “… chemical recycling as a complementary option for waste that cannot be recycled mechanically, if it causes less environmental burden than incineration and virgin plastic production.”

Chemical recycling can create petrochemicals from plastic waste

Petrochemicals are critical components in many, perhaps most, industrial and consumer products. Currently, petrochemicals are made from non-renewable fossil fuels, primarily crude oil.

According to the World Economic Forum3, reducing the chemical industry’s need for fossil-based petrochemicals by using plastic waste-based alternatives can potentially save 300 million tons of fossil-embedded greenhouse gas emissions annually.

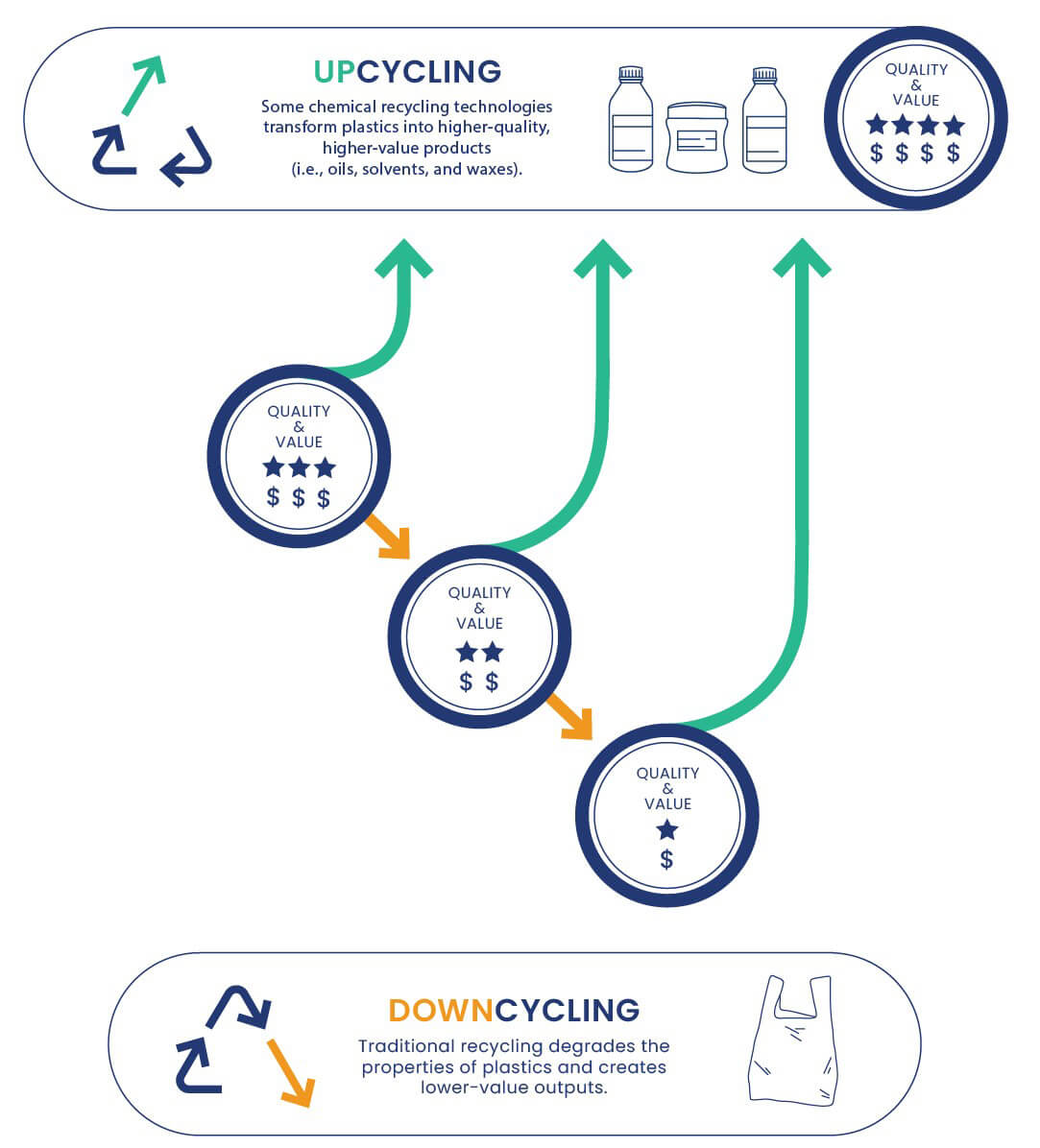

Currently, most plastic waste recycling is “downcycling” – the value of recycled products is lower than that of products made from virgin plastics because traditional recycling degrades the physical properties of the material being processed.4 Mechanical recycling does not depolymerize its feedstock and, therefore, can only create plastic of the same type as its feedstock. In contrast, chemical recycling via thermal cracking depolymerizes plastic and, therefore, is not restricted to plastic-to-plastic recycling.

Moreover, chemical recycling can handle some plastic types that are difficult or impossible to recycle mechanically, like ultra-high-molecular-weight polyethylene (UHMWPE) and wider mixes of plastics with lower quality and higher levels of contamination.

When a process creates outputs with a higher value than the original, it is known as “upcycling”. Chemical upcycling can produce petrochemicals – oils, solvents, and waxes that can serve as alternatives to fossil-based oils, solvents, and waxes.

Upcycling salvages plastics from an inevitable degrading downcycling path

Plastics undergoing traditional recycling degrade in physical and compositional quality and value. Upcycling transforms plastics into new materials with higher value and quality.

Circularity keeps materials within the economy longer and reduces waste

The term “circular economy” appeared for the first time in 1990.5 A popular definition states that “a circular economy is a model of production and consumption in which […] the life cycle of products is extended […] reducing waste to a minimum [with] materials kept within the economy [and] productively used again and again, creating further value”.6

The concept of circularity is a response to the prevailing “take-make-use-dispose” linear economic model at the root of the plastic waste epidemic. It is gaining momentum, with governments and international organizations developing strategies to transition to a circular economy. A circular economy is a system where resources are kept in use for as long as possible, extracting their maximum value before recovering and regenerating them.7 Such a system reduces waste and the need for new resource extraction.

The most straightforward and intuitive interpretation of circularity is “X to X” – taking a product or material that is no longer in use or no longer usable, processing it, and returning it to use. In the case of plastic waste, this usually means “plastic to plastic” – processing plastic waste into another form, such as pellets or granules, which is used to make new plastic products.

The current academic8 and policy9,10 discussion focuses primarily on plastic circularity in terms of plastic-to-plastic.

Plastic circularity can and should include plastic-to-products

In 2018 McKinsey & Company published a comprehensive review of the plastic recycling sector titled “No Time to Waste”.11 In the paper, the authors argue that “it’s possible to imagine a whole new configuration of petrochemical and plastics plants” and call companies to “think big and bold”. I agree. In fact, I argue that it is also possible to imagine a whole new configuration of the entire hydrocarbon industry.

There is no reason to restrict plastic circularity models to consist of only plastic-to-plastic. Circularity is not an end but a means to an end – reducing natural resource extraction and waste creation (the hallmarks of the linear economy). The benefits of circularity – keeping materials in the economy instead of discarding them – are furthered by transforming plastic waste into new valuable materials, not just plastic.

Increasing the conceptual scope of circularity will increase recycling levels not only by opening additional avenues and markets for circularity but also by making these avenues more commercially attractive and profitable. This is the advantage of upcycling – transforming plastic waste into outputs whose value is higher than that of the original, previously discarded products.

Plastic-to-products circularity is gaining momentum in new policy

In March 2022, the European Commission published a proposal for a regulation that will promote product sustainability through eco-design. The proposed regulation, called “Ecodesign for Sustainable Products Regulation (ESPR)”, will, among other things, set requirements for recycled content in product groups, including intermediate products.12 A preliminary assessment has already identified product categories such as detergents, paints, and lubricants.13 Therefore, it is likely that materials such as waxes, oils, and solvents made from plastic waste that are used to create end-products such as those mentioned above, will be recognized by the ESPR as “recycled content”. This is a sensible and valuable development since any useful material that is made from 100% plastic waste is truly upcycled and not just recycled into more plastic.

In January 2023, the US Department of Energy published its “Strategy for Plastics Innovation” 14.

This paper acknowledges that “upcycling efforts generate valuable products from discarded plastics” and explicitly includes upcycling as a path “which must be considered holistically to enable a plastics circular economy.”

Lastly, as mentioned above, the EC published “Transition Pathway for the Chemical Industry”15 – a plan to make the European chemical industry more environmentally-friendly and sustainable. The document argues that “Certain ‘breakthrough upcycling’ technologies are now commercially scalable. In these technologies, a wide range of plastic waste, including difficult-to-recycle plastics, is recycled at high efficiency into high-purity products (such as waxes, oils and solvents) that can be used in a wide range of industries. These innovative and sustainable business cases require only plastic waste as raw material, enabling the circular production of fossil-free chemicals.”

Unlocking the sustainability potential of the chemical industry with broad circularity

In the face of environmental challenges such as pollution and climate change, the industrial world is shifting toward more sustainable and environmentally friendly modes of production, with circularity serving as a core concept. The chemical industry is one of the largest consumers of fossil feedstocks and is looking for alternatives. Now, chemical recycling technologies can provide one – plastic waste.

Using plastic waste as a source for green petrochemicals is not just a more sustainable path for the chemical industry but also can reduce global plastic pollution by increasing demand for plastic waste. When upcycled products have a higher value than new plastic products, a new catalyst for the circular economy is created. A higher value increases demand for plastic waste, which increases the incentive to prevent valuable plastic waste from exiting the system by being dumped in landfills, the ocean, or incinerated into the atmosphere.

It is high time that the chemical industry turns to plastic waste as a resource that replaces fossil fuels. So far, the industry’s key focus has been reducing/greening energy usage. But now, transitioning the feedstock side towards sustainability is becoming another promising approach. Now, plastic waste is a valuable resource that can be used for much more than only recycled plastics.

Plastic-to-products upcycling has several features that make it a particularly promising source of feedstock for the chemical industry:

- It does not compete directly with mechanical recycling for raw materials because it can take a broader range of plastic waste inputs than what mechanical recycling can.

- It does not compete with mechanical recycling for customers since it does not produce plastic.

- It utilizes the full potential of low-grade plastic waste, hence providing a more comprehensive and compelling solution to the plastic waste epidemic.

- Its technical capabilities are already available and can be implemented in the value chain without disruption.

Conclusion

Circularity is not a goal but rather a conceptual tool for promoting sustainability and environmental protection. Circularity does not mean material A must be recycled into new material A and B into B. If material A can be recycled into multiple materials or products, choosing the most valuable option best serves the goals of circularity – keeping the material (in our case – carbon) within the economy and reducing the extraction of virgin materials (in our case – fossil fuels) from the earth. In concept and implementation, broader circularity is better circularity.

Plastic circularity does not have to be restricted to plastic-to-plastic, and the advantages of a broader concept of circularity are gaining recognition by policymakers. This understanding is being manifested in policy papers such as the EC’s “Transition Pathway for the Chemical Industry,” and “Ecodesign for Sustainable Products Regulation”, and the US Department of Energy’s “Strategy for Plastics Innovation”.

It is time for the chemical industry to join the cause and begin switching from fossil-based petrochemicals to sustainable plastic waste-based ones.

1 EUR-Lex – 52020DC0667 – EN – EUR-Lex (europa.eu)

2 https://ec.europa.eu/commission/presscorner/detail/en/QANDA_22_2014

3 The chemical industry can wean itself off fossil feedstocks. Here’s how | World Economic Forum (weforum.org)

4 Why the “New Plastics Economy” must be a circular economy (openedition.org)

5 https://www.worldcat.org/title/economics-of-natural-resources-and-the-environment/oclc/20170416

6 https://www.europarl.europa.eu/news/en/headlines/economy/20151201STO05603/circular-economy-definition-importance-and-benefits

7 The circular economy (spglobal.com)

8 A review of the plastic value chain from a circular economy perspective – ScienceDirect

9 https://www.mckinsey.com/industries/chemicals/our-insights/no-time-to-waste-what-plastics-recycling-could-offer

10 https://www.oecd-ilibrary.org/environment/global-plastics-outlook_de747aef-en

11 https://www.mckinsey.com/industries/chemicals/our-insights/no-time-to-waste-what-plastics-recycling-could-offer

12 https://ec.europa.eu/info/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/sustainable-products/ecodesign-sustainableproducts_en

13 https://ec.europa.eu/commission/presscorner/detail/en/QANDA_22_2014

14 U.S. Department of Energy Strategy for Plastics Innovation Report

15 https://ec.europa.eu/docsroom/documents/53754